Like caulking windows, air infiltration, moisture, insects and mold are signs that a door is poorly insulated and requires weatherstripping.

Like caulking windows, air infiltration, moisture, insects and mold are signs that a door is poorly insulated and requires weatherstripping.

All openings are subject to air and moisture infiltration, which results in medium- and long-term degradation of woodwork and buildings.

Air infiltration is an energy loss that increases your heating or air conditioning bills depending on the season.

The quickest way to address this phenomenon is to plug the spaces around your door.

For this, there are cold cutters or insulating ribbons. These materials are resistant to sun and humidity. But these are temporary or complementary solutions to caulking because cold cutters are fragile and ineffective in the long term.

Your caulking technicians in Montreal explain the different door caulking techniques inside

What is a Weatherstripping?

A weatherstripping is usually made of flexible materials such as rubber, silicone, or PVC, which are specially designed to withstand temperature variations and weathering. When installed correctly, weatherstripping creates a hermetic barrier around openings, preventing unwanted drafts from entering the building.

The different types of weatherstripping

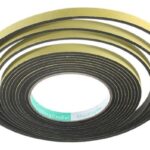

There are several types of weatherstripping available on the market, suitable for different door and window configurations. Adhesive weatherstripping is easy to install and is generally suitable for temporary applications. Foam weatherstripping is also popular because of its ability to effectively seal small openings and cracks. For more permanent applications, rubber or silicone weatherstripping offers superior durability and strength.

The advantages of properly installed weatherstripping

A properly installed weatherstripping offers many benefits to the owners and occupants of a building. In addition to saving energy and reducing heating and cooling costs, it also improves indoor comfort by eliminating cold drafts and cold spots. In addition, by enhancing thermal sealing, weatherstripping helps extend the life of heating and cooling equipment, reducing long-term maintenance costs.

Weatherstripping insulation tape for doors

A wooden door can play out over time because of variations in temperature and drying of its wood for example.

When the building is old, the foundations and foundations can also move and pass these movements on the woodwork of the openings.

All these movements create “days” at the doors and sometimes windows.

The cooler is then installed to prevent air from seeping between the door and its frame when it is closed.

If this “calfeutre” function in a certain way, it cannot be considered professional caulking, which applies only outside the home.

The cold cutter is found in various forms ranging from the foam tape to the rubber band and the aiming profile, the shape of which is more or less elaborate according to the brands.

Simply attach this strip around the door to provide waterproofing to the perimeter by limiting the passage of air. The foam tape is a sticker while the rubber band or profile is screwed or nailed to the door frame.

The downside is that these insulating products are crushed during successive door openings and closures and while the foams degrade by breaking, polyurethane or rubber profiles dry over time.

The insulating tape must therefore be renewed regularly. This DIY is not recommended in a frequent place of passage such as the main entrance door or in a public place for example.

The rubber band is more durable over time because it acts as a spring that mechanically resists more demands.

The door threshold cutter

Usually made of metal with a flexible rubber slat, the door threshold cut is fixed on the floor or on the framing at the bottom of the door, depending on the models. It should be replaced fairly regularly because the rubber can tear over time and passages. It loses its waterproofing action.

Poor waterproofing causes several problems:

- Air and moisture infiltration;

- Discomfort for the locals;

- An increase in energy bills (heating or air conditioning costs);

- Deterioration of woodwork and interior paints;

- Excessive condensation that can lead to mould;

- Easy penetration of pests or rodents;

It should be noted that all these techniques are effective in the short term and do not allow long-lasting thermal insulation of your parts.

This is why the work of the caulking expert makes it possible to propose an optimal waterproofing of your home, especially in Quebec where the amplitude of temperatures is very variable.

To do this, building technicians use insulating and resistant caulking sealants.

Different types of cold cuts

This open-cell urethane foam and polyethylene sheath joint is resistant to long-term use.

A magnetic stripe allows adhesion to the door. It retains its initial shape for a very long time and helps to seal the doors. The PH2MAG model is mainly used for front doors and is installed in a saw stroke. (Atservitek)

This type of cold cut screws on the door studs, its mechanical properties allow it to withstand the crush while adapting to the “gap” that exists between the door and its frame.

It’s a good choice to renew at 5 years old.

Garage door coolers are made of rubber and PVC seals (vinyl polychloride) installed around the perimeter and at the foot of the garage door. In addition to humidity and cold, they prevent unwanted insects and rodents from entering the garage.

Cold cut band with sealing barrier.

Material: Polypropylene

Fixation: self-stick

Sustainability: short

Strength: quickly laid

Weakness: picks up dust

The Government of Canada recommends the laying of the bise cuts with this video.